Most people have no idea about plasma and its role in making our lives easier. While its wonders still sit in a grey area, plasma technology will soon create a huge impact that even late adopters could easily catch up.

The automotive industry is one of the luckiest sectors that will benefit from the ever-improving plasma processes. With many individuals taking varying amounts of mania in owning or at least driving a fancy car or motorcycle, it’s just a matter of time until everyone gets accustomed to the science behind them.

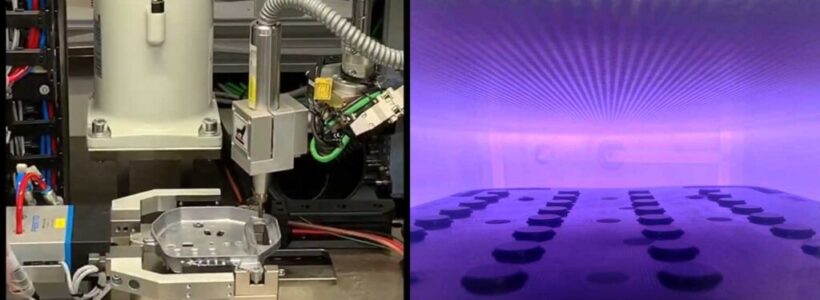

There are different plasma systems and solutions used by many industries worldwide. It can coat, etch, clean, and activate surfaces. However, plasma treatment, reactive ion etching (RIE), and plasma cleaning are the most used applications in the car industry. Learn more about plasma systems, RIE, and other industrial applications.

In layperson’s terms, plasma treatment processes are used to alter the surface properties of different materials, so it’ll be easier to glue, paint, or bond them. Besides the chemical changes applied to a fabric or plastic, the technology may also improve its quality.

But how exactly does plasma technology influence the automotive industry?

With the above description of how plasma treatment works, the obvious detail suggests an easier production and construction of car body shells. After all, it talks about altering “surface” properties.

However, plasma technology goes beyond what the naked eye can see. Thus, it may apply to the production of both exterior and interior car parts. A quick discussion about surface energy should give anyone a better idea.

Surface Energy Quickly Explained

Also called interfacial free energy or surface free energy, surface energy talks about the force that produces a new surface.

Let’s say a tiny drop gently falls on a surface but does not collapse. Due to the reactions that took place at a molecular level, a surface tension phenomenon occurs, which subsequently creates a thin film layer. This thin layer is what lets the drop maintain its shape. If the surface is inclined and there’s no change in force applied, the droplet will reach the end of the same surface without losing its mass.

The surface energy is described as the work done per unit area to produce this layer. If the surface has low surface energy and the impact during the fall isn’t that strong, it won’t repel the drop. Modifying this surface energy is the key to producing efficient materials for automobile production.

Plasma treatment processes aim to increase the surface energy of various materials to improve their bonding characteristics. In car production, plasma technology enhances the adhesion of a wide array of interior and exterior automotive parts without heat issues encountered compared to using flame surface treatment.

Without further ado, below are ways plasma treatment has changed automotive technology.

Painting Plastic Materials

Compared to metals, it is much more difficult to paint or bond with plastic car parts. Painting plastic requires a clean surface so the paint can bond easily and evenly to plastic and other composites that may be involved.

This scenario is where the plasma cleaning process steps in. It removes impurities, contaminants, and other elements from surfaces that may hinder bonding or painting. The method uses energy plasma or dielectric barrier discharge plasma derived from gaseous species.

With these steps, car manufacturers can achieve fully clean plastic and seamlessly painted plastic surfaces that match the color and texture of metal exteriors. On top of that, plasma activates the surface, which prevents the paint from peeling off!

As plasma technology improves, paint resistance on cars may increase their durability against minor scratches and accidents. It’s a promising feat for car enthusiasts who want to keep their autos in tip-top and sparkling condition.

Headlights and Tail Lights That Last A Lifetime

Modern headlights and tail lights have earned great longevity thanks to plasma coating techniques that use a plasma polymer. Bonding parts made of polypropylene (PP) and polycarbonate (PC) require adhesion with excellent sealing properties. Thus, plasma activation stimulates non-polar materials in these critical regions, ensuring the long-term sealing of headlights and tail lights.

Surprisingly, plasma processes are cost-effective in increasing the lifespan of headlights and tail lights, considering their ability to prevent housing deformations and corrosion of reflective surfaces. The same can be said in manufacturing and bonding windshields, windows, and other materials that need reinforcement.

Soon, top-of-the-line cars in the market may showcase invincible headlights, and tail lights immune from all types of damage as more advanced plasma solutions are discovered.

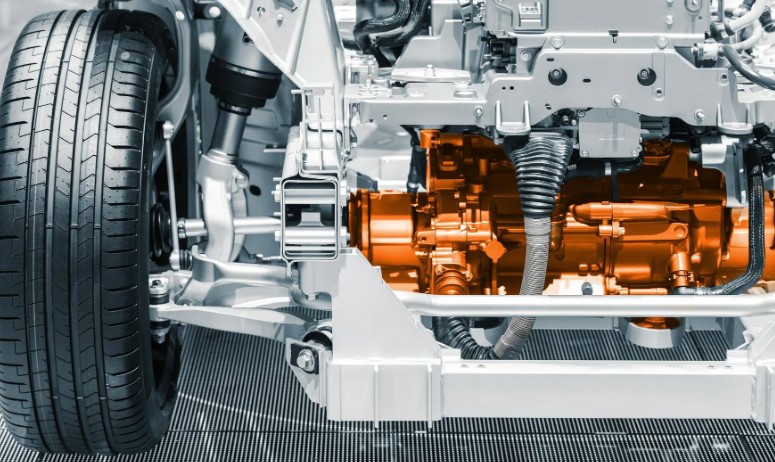

Electromobility and Other Electrical Components

Leading automobile manufacturers aim for higher efficiency drive and storage systems. Thus, electromobility will be at the center of the development efforts of these companies.

Ideal electric motors, batteries, and fuel cells of the future are light and have higher capacity. Manufacturing these high-performance systems is crucial to staying ahead of the competition. At the same time, these parts have to be resistant to harsh environments, including different chemical reactions that may take place.

Therefore, automobile manufacturers are racing to produce the best innovative material composites critical to building these ambitious systems. Moreover, they also need to think of cutting-edge features such as additional sensors and accelerometers for autonomous machines, which bonding strengths are enhanced by plasma surface activation. The constant development of plasma treatment, activation, and coating solutions can take car technology to another level.

On the other hand, plasma etching allows a more reliable way of building car computer components, especially with the self-driving feature in mind. Plasma can dry etch circuit boards compatible with this technology, and this dependable process can result in safer and more innovative self-driving cars in the future.

The Future Of Cars With Plasma Technology

As innovation computerizes car technology, the automotive industry will rely on more plasma solutions to achieve new heights. Besides navigation features, self-driving, Bluetooth access, and web browsing, cars may soon offer unexpected features.

When manufacturers realized the benefits of plasma treatment and other processes, the possibilities evolved from limited to endless. All we can do for now is keep our eyes open for what plasma has in store for us in the years to come!