As long as there are cars and trucks on the road, there will need to be ways to fix them. Over time even the best vehicles experience normal wear and tear and have components that need replacing. Whether you want to repair your own cars in the future or start a business fixing other people’s vehicles, you’ll need some supplies for your workshop.

Organizing a Car Workshop

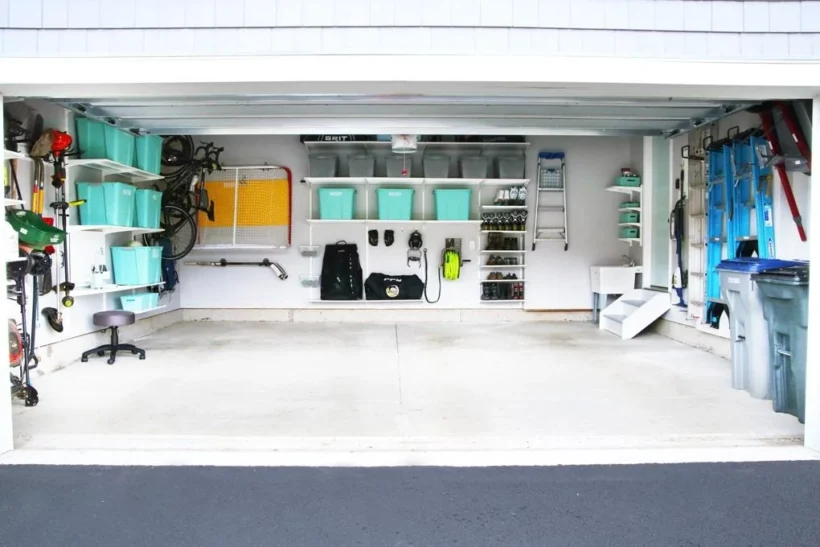

To get started, you need to get organized. Whether it’s your personal garage or your new auto shop space, evaluate the layout and area you are working with. Make sure the room is big enough to easily get around the cars you will be repairing while still having space for storage.

Speaking of storage, your car repair space will need a place to store a wide variety of tools, including hand, power, and specialized tools. Tool cabinets from Rogo Fastener are made to work in a mechanical shop so you can keep your supplies and tools where they need to be.

Parts bins and storage containers, such as plastic bins or metal bins, can be used to store small parts and components. These bins can be labeled and organized by type, size, or use, making it easy to find the parts that are needed.

Equipping Your Shop

Next, you need the necessary equipment and tools. A car workshop will hand tools, power tools, diagnostic equipment, and specialized tools for specific tasks. Investing in high-quality items makes it easier to get your job done and gives you confidence that these items will last.

Remember to buy smaller supplies as well. Large items such as brake pads are obviously important, but so are clamps, o-rings, screws and brackets. These little parts are easy to get from Rogo Fastener and are necessary for a successful car repair.

Get the Right Lighting

Proper lighting is an important consideration in any automotive shop. Good lighting helps mechanics see what they are working on more clearly, which can help them identify problems and make repairs more efficiently. Even in a small workshop, you need to be able to see the details of a part or component that you are working on.

The lighting should be bright enough to allow mechanics to see all the details of the work they are doing. This may require using higher-wattage bulbs or installing additional light fixtures. It’s generally best to use bulbs with a bright white light that is easy on the eyes. Place light fixtures in a way that helps mechanics see every part of the work area. This may require installing lights above work benches or in other strategic locations. Rogo Fastener has lights that can go where you need them.

Outfit Your Auto Workshop Today

A well-run auto repair shop or workshop is a great asset to have. By getting the right organizational tools, parts and equipment, you can make your shop ready for jobs big and small. Start finding the things you need for your shop and get to work today.

Safety and Compliance

Safety and compliance should be a top priority when organizing any auto workshop. When conducting maintenance or repairs, it is important to take into consideration the risks posed by hazardous material, potential fires, and moving parts.

The National Institute for Automotive Excellence (NIAE) emphasizes safety best practices for auto technicians and staff. These recommendations include:

- Establishing guidelines for proper disposal of hazardous materials such as used oil and coolant.

- Ensuring that suitable fire extinguishers and other safety equipment are readily available.

- Putting in place protocols and procedures to deal with emergencies efficiently.

- Providing proper protective clothing and tools.

- Setting up safe access and egress points throughout the workshop.

- Regularly checking on the tool condition in order to minimize or eliminate potential hazards.

Workflow Strategies

Having an efficient workflow in an auto workshop environment is essential to ensure that tasks are completed on time and that customer expectations are met. To increase workflow efficiency, it’s important to analyze current working practices and determine optimal processes, based on the needs of the workshop.

Workflow strategies should be deployed in a systematic manner, starting with layout changes such as setting up the workshop equipment based on frequency of use. This includes adjusting maintenance frequencies of equipment and keeping necessary parts close at hand. Implementing standard operating procedures (SOPs) can help minimize mistakes and ensure that each part of a repair job is completed thoroughly and correctly. SOPs should detail processes for delivering services, interacting with customers, inspecting vehicles for safety, diagnosing problems, as well as scheduling repairs or maintenance work.

In addition to SOPs, auto workshops can benefit from implementing technology-enabled workflow strategies such as barcode scanning for parts inventory tracking or real-time job information sharing through mobile devices or tablets. Automating inventory management helps reduce paperwork while saving staff time and improving accuracy. Automating job information creates smooth operational processes between personnel and customers, which increases customer satisfaction.

Overall, successful implementation of workflow strategies requires clear communication across all staff members in order to consistently follow the standards established by management or organizational leaders. It’s important for team members to understand their roles for each job so that jobs are completed quickly with minimal disruption in customer service delivery levels and satisfaction. Furthermore, effective workflow strategies also need regular review procedures so that any systemic issues can be identified quickly allowing leadership teams to address them promptly before they become bigger problems resulting in customer dissatisfaction or revenue loss.

Conclusion

The layout of an auto workshop should be designed with efficiency in mind. The goal should be to set up a work area that enables mechanics to locate parts and tools easily. To ensure an efficient work environment, managers should allocate adequate space for each station and area in the workshop. Proper organization is essential for maximizing the efficiency of auto technicians and ensuring their safety while on the job.

To help meet these goals, there are numerous organizational strategies that managers can use, including:

- Talking with experts

- Creating organized floor plans

- Setting up well-designed storage systems

By taking the time to plan thoroughly and adopt a system that works best for their specific needs, managers can create a workspace that is both efficient and safe.