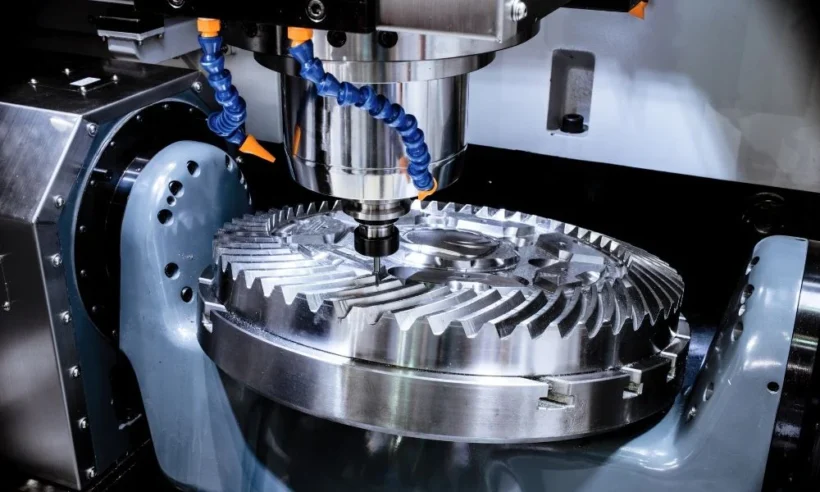

While the automotive industry remains one of the most advanced sectors in terms of cutting-edge technology and materials, CNC custom machining still plays an important role in many aspects of production. The status quo of CNC custom machining within this sector is largely dictated by a number of factors, including strict safety regulations, material costs, and increased demand for highly specialized components. However, despite these challenges, CNC custom machining continues to be essential for everything from prototyping new parts to manufacturing complex assemblies on a large scale. Ultimately, its versatility and precision make it an indispensable tool for modern automotive manufacturers.

The History of CNC Custom Machining in the Automotive Industry

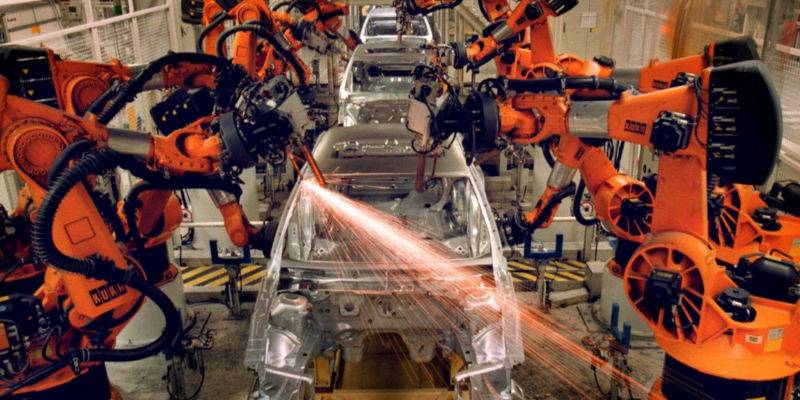

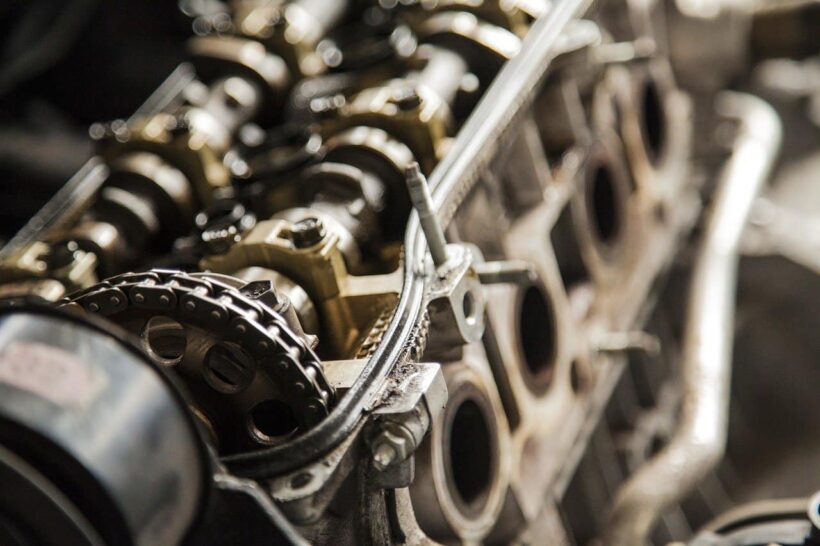

CNC machining first began appearing in automotive manufacturing in the 1960s as a way to quickly and accurately create prototypes and small production runs. In the 1970s, as CNC machines became more affordable and reliable, their use began to spread throughout the automotive industry. Today, CNC machines are an essential part of any modern automotive manufacturing facility, used for everything from creating engine parts to shaping exterior panels.

One of the most iconic cars to ever come out of the automotive industry, the Volkswagen Beetle, was actually heavily reliant on CNC machining. The car’s distinctive shape was created using a CNC router, and its engine parts were all produced using CNC milling machines.

CNC machining has also played a major role in the development of electric vehicles. Many of the parts that make up an electric car, such as the battery pack and motor, require extremely precise manufacturing tolerances that can only be achieved through CNC machining.

How CNC Machining Is Changing the Way Automakers Do Business

CNC machining is changing the way automakers do business. In the past, automakers would outsource the majority of their machining needs to suppliers. However, nowadays, increasingly, automakers are investing in their own CNC machining capabilities. This shift is driven by a desire to better control quality, costs, and lead times.

Outsourcing your machining needs to a supplier in China can be a great way to save money. Chinese suppliers have become very experienced in providing high-quality CNC machining services at competitive prices.

However, there are some potential risks associated with working with a Chinese supplier. These include quality control issues, communication difficulties, and long lead times.

As automakers increasingly look to control their own destiny when it comes to CNC machining, we will see more investment in this area. This shift could have a major impact on the way that parts are sourced and manufactured in the automotive industry.

The Benefits of Using CNC Custom Machining in the Automotive Industry

Some benefits of using CNC Custom Machining in the automotive industry include:

- Increased accuracy – When creating custom parts for cars and trucks, it is essential that they are made to precise specifications. CNC Custom Machining provides a high degree of accuracy, ensuring that parts fit together perfectly and perform as intended.

- Repeatability – In order to mass produce parts, it is essential that they can be made consistently. CNC Custom Machining allows for parts to be reproduced exactly, ensuring that each one meets the same high standards.

- Cost-effective – CNC Custom Machining can be used to create prototypes or small production runs of parts, which can save on manufacturing costs.

- Quick turnaround – CNC Custom Machining can be used to produce parts quickly, which is essential in the automotive industry where time is of the essence.

The Challenges Faced by CNC Custom Machining in the Automotive Industry

CNC custom machining offers a number of advantages over traditional manufacturing methods, such as shorter lead times, lower costs, and greater flexibility. However, it also comes with its own set of challenges in the automotive industry.

Lead time: One of the biggest challenges facing CNC custom machining is lead time. Due to the complexity of the process, it can often take weeks or even months to produce a single part. This can be a major problem for manufacturers who are trying to meet tight deadlines.

Cost: Another challenge facing CNC custom machining is cost. Although the initial investment in equipment and training can be high, the long-term costs are usually lower than traditional manufacturing methods. However, there can be a number of hidden costs associated with CNC custom machining, such as tooling, fixturing, and programming.

Quality: A third challenge facing CNC custom machining is quality. In order to produce parts that meet the highest standards, manufacturers need to invest in high-quality equipment and training. This can often be a challenge for small and medium-sized businesses who may not have the budget for these things.

Conclusion

CNC Custom Machining has been a part of the automotive industry for many years, helping to create some of the most iconic cars and trucks ever made. As the automotive industry and technology continues to evolve, we can only imagine what new and innovative ways CNC machines will be used in the future.